Standardized Recipe Development and Implementation

The backbone of any successful restaurant’s flavor consistency lies in standardized recipes that eliminate guesswork entirely. These comprehensive guides specify exact measurements, cooking times, temperatures, and techniques to ensure each dish is prepared with the same ingredients, measurements, and techniques across locations. Think of standardized recipes as the DNA of a dish – they contain every piece of genetic information needed to replicate that perfect flavor profile time and again.

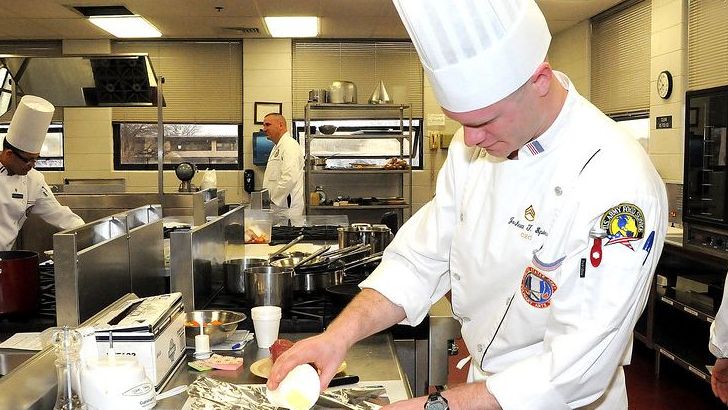

Well-crafted standardized recipes specify exact measurements, cooking times and temperatures, plating instructions, and even visual references to ensure that every dish looks and tastes exactly as intended. Many successful restaurant operations go beyond simple ingredient lists by posting photographs of each completed dish in kitchen areas. This visual approach helps workers understand exactly what the final product should look like, creating consistency not just in taste but in presentation as well.

Strategic Seasoning and Timing Techniques

Seasoning means to bring out or intensify the natural flavour of the food without changing it, with seasonings usually added near the end of the cooking period. Professional kitchens understand that timing is everything when it comes to salt, pepper, and acids like lemon juice. The goal isn’t to taste the seasoning itself – it’s to heighten the flavors of the original ingredients.

Fresh seasonings are added late in the cooking process while dry ones tend to be added earlier, and it is good practice to under-season during the cooking process and then add more seasonings just before presentation. This layered approach to seasoning creates depth and complexity that keeps customers coming back. Smart chefs know that a dish seasoned properly at every stage will taste dramatically better than one that gets all its salt at the end.

Precision Temperature Control Systems

Temperature variations can enhance or alter the taste and texture of dishes, with physical and chemical changes occurring during cooking that reveal how variations in temperature can enhance or alter the taste and texture. Professional restaurants invest heavily in precise temperature control because even small variations can dramatically impact flavor development and consistency.

Consistency in cooking temperatures, portion sizes, and cooking times is vital for maintaining food quality, with equipment like ovens, fryers, and grills regularly calibrated and maintained to perform optimally. The Maillard reaction, which creates those irresistible caramelized flavors on grilled meats, only occurs at specific temperature ranges. Without proper control, you might get a pale, flavorless exterior instead of that perfect golden-brown crust that makes dishes memorable.

Comprehensive Staff Training Programs

While standardized recipes provide the blueprint for consistent food quality, it is the restaurant’s staff who bring those recipes to life, with comprehensive and ongoing staff training essential to ensure that every member of the culinary team understands and can execute the restaurant’s quality standards flawlessly. Training goes far beyond showing someone how to follow a recipe – it’s about understanding the why behind each technique.

Comprehensive training programs that keep chefs and kitchen staff up to the mark should cover the importance of a consistent experience, provide detailed instruction on standardized recipes, and come with plenty of hands-on practice. Successful restaurants implement ongoing education programs that keep teams updated on the latest techniques and best practices. This continuous learning approach helps maintain uniform high standards and ensures experienced knowledge transfers to new team members effectively.

Strategic Supplier Quality Control

Centralized purchasing and supply chains help maintain consistency across locations by sourcing ingredients from the same suppliers and ensuring they meet uniform standards, reducing variability in food quality between locations. Smart restaurants understand that consistency starts long before ingredients hit the kitchen – it begins with choosing reliable partners who can deliver the same quality products day after day.

Seasonal changes, supply chain issues, or variability in ingredient quality can all affect consistency, making it essential to have clear guidelines for handling ingredient variability and standardizing how to adjust recipes when ingredient quality or flavor varies. Top-performing restaurants develop relationships with multiple suppliers and create backup plans for when primary ingredients aren’t available. They also train their staff to recognize quality variations and adjust cooking techniques accordingly.

Regular Quality Audits and Taste Testing

Regular audits of every location serve the purpose of assessing and verifying that the establishment’s ambiance, cuisine quality, and service standards are met, playing a pivotal role in guaranteeing that every franchise is in accordance with the brand’s fundamental principles and operational benchmarks. These audits can be scheduled or surprise visits, but they’re absolutely crucial for maintaining standards across multiple locations.

Quality control measures should be implemented at every stage, from receiving and inspecting ingredient deliveries to plating and serving the final dish, including conducting regular inspections of incoming ingredients and monitoring critical data points such as refrigerator and cooking temperatures. Smart restaurants create systematic taste-testing protocols that evaluate not just flavor, but also texture, temperature, and presentation. These regular checks help identify problems before they reach customers.

Advanced Equipment Standardization

A lack of standardization across kitchen equipment can contribute to variability in restaurants, as different stoves, ovens, and mixers can lead to variations in cooking times and temperatures. Many successful chain restaurants solve this problem by installing identical equipment across all locations, eliminating one major variable that could affect taste consistency.

Tuff grills, tailored for industrial and restaurant purposes, are engineered for durability, even heat distribution, and ease of cleaning – all pivotal for high-volume cooking. When identical equipment isn’t feasible due to space or budget constraints, smart operators adapt their recipes to account for equipment differences. They might adjust cooking times or temperatures to compensate for variations in how different ovens distribute heat.

Technology-Enhanced Precision Tools

Digital food thermometers, portion control devices, and automated cooking equipment reduce the chance of human error during the preparation process, while real-time data collection and analysis tools provide important insights into areas that may need improvement. Modern restaurants leverage technology to remove guesswork from the cooking process, using digital scales that measure ingredients to the gram and timers that ensure perfect cooking intervals.

Technology enhances efficiency and accuracy in quality assurance through digital temperature monitoring, automated inventory management, and POS system analytics that help maintain food safety and operational consistency. Some cutting-edge operations use recipe management software that guides cooks through each step, ensuring nothing gets forgotten during busy service periods. This technological approach helps maintain consistency even when experienced staff members aren’t available.

Strategic Menu Engineering and Flavor Profiling

Different categories blend in playful ways, creating unique dishes and drinks, with restaurants and packaged foods experimenting with surprising combinations like citrus and spicy or sweet and savoury, offering consumers new sensory delights. Successful restaurants don’t just focus on individual dishes – they engineer their entire menu to create complementary flavor profiles that work together harmoniously.

Sauces that combine spice with crunch, sweetness, or fermented depth consistently outperform single-note heat, with every flavor building an emotional and sensory arc. The most successful restaurants understand that layering different flavor components – acid, salt, fat, heat, and umami – creates more memorable and craveable dishes. They might use techniques like finishing oils, compound butters, or house-made pickles to add those extra layers of complexity.

Customer Feedback Integration Systems

Listening to customer feedback provides valuable insights into service quality and menu performance, with restaurants actively collecting and analyzing feedback through surveys, online reviews, and direct interactions. Smart operators don’t just collect feedback – they analyze patterns and use that data to make informed adjustments to their recipes and preparation methods.

Customer feedback is important for flavor consistency because it helps identify inconsistencies, allowing restaurants to adjust and maintain quality across all locations. The best restaurants create systematic approaches to gathering and responding to feedback, whether through digital surveys, comment cards, or staff observations. They track specific complaints about taste, temperature, or presentation and use that information to refine their standardization processes continuously.